Well, I’ve met Paul the Tomcat man and we had a long chat (a very long chat, punctuated by a lot of telephone calls. Poor Paul hardly got any work done) about the various options available and the different ways of doing things. Co-driver Nase (who is a rather freakish 6’7″ tall) also had a sit in one, and proclaimed it to have “enough room”.

This Tomcat has a 4.0l TVR engine

(Note – click on any of these pictures to go to my Flickr account where the picture is stored. On Flickr you can click on the small ‘all sizes’ button at the top of each photo to see a larger version)

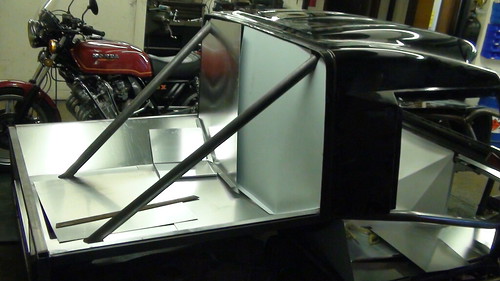

The rear of a truck-style Tomcat, with spare wheel and rear floor pan.

There was plenty to look at, from a 5.0l TVR-engined rocket ship to a naked roll cage on a chassis. Paul talked us through how the cage was put together and fitted to the chassis, and how the engine is moved backwards to improve the stability.

This shows the rear of the Tomcat. Note where the chassis has been cut.

He also explained that although it could be hard work, it wasn’t overly technical. The design was simple and the amount of technology involved is up to you – if you want to turn your automatic into a flappy-paddle semi-auto, that’s possible. Upgraded engines, axles, prop shafts, diffs, brakes, suspension and pretty much everything else is available, too. If you want to use as much of your original vehicle as possible (which I do), that’s fine too.

An experimental rear-engined Tomcat.

So now it’s down to me to decide what I want to do so Paul can get a quote together for me. Prices can vary depending on what you want, and how much of it you want to be done by Tomcat for you. I’ll put my thoughts about that in the next post.

The insides are basic, to put it politely. Hopefully mine will have a steering wheel.

I took a whole bunch of pictures – you can see them in a Flickr group here.